Address: No. 188, Xin Zhan North Road, Zhangjiagang, Jiangsu

Contact: Mr. Cao

Cell phone: 13806227123

Phone: 0512-58968100

Fax: 0512-58968100

Zip code: 215600

E-mail:1197414559@qq.com

Web site: 59mq.cn

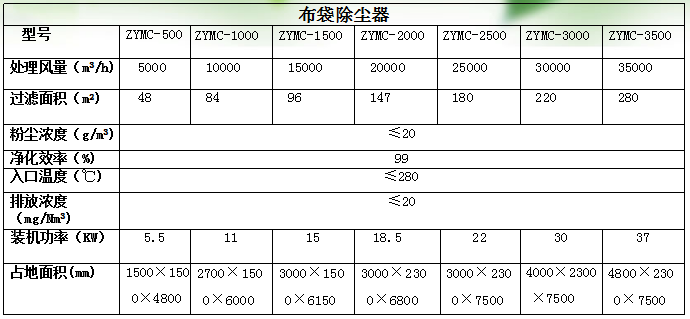

Bag-type dust collector

![]()

Mainly used in the ironmaking plant, steel plant, ferroalloy plant, refractory plant, foundry plant, power plant flue gas dedusting system of MSW incinerator, coal-fired boiler, fluidized bed boiler flue gas filter. Asphalt concrete, building materials, cement, lime, gypsum and other ceramic production sites. Smelting aluminum electrolysis flue gas filter, lead, tin, zinc, copper and other precious metals, fine material recovery, liquid and solid solid separation. Chemical industry, coke, carbon black, dyes, pharmaceuticals, plastics etc liquid and fine material recycling. Mining, food processing, flour, electronic industry, wood processing and other dust control and purification.

![]()

Pulse bag filter by the bucket and upper box, in the box and a lower box part, and the box section structure. When the dust laden gas into the hopper by the air inlet duct, coarse dust particles directly into the bottom of the ash bucket, fine dust particles with the air flow turning upward into the middle and lower box, dust deposition on the surface of the filter bag, the gas after filtered into the box on the net to set gas pipe exhaust duct, the exhaust fan to exhaust the atmosphere. The cleaning process is to cut off the air outlet duct of the room first, so that the cloth bag in the room is in the state of no air flow through the air. Then open the pulse valve with compressed air pulse jet cleaning, shut-off valve closing time to ensure in the blowing dust bag after stripped from the settlement to avoid the dust in the hopper, and then with the air from the surface of the filter bag attached to adjacent set bag surface phenomenon, make the bag cleaning thoroughly, and the programmable program control instrument on the valve and exhaust valve, pulse discharging valve and automatic control of the whole.

![]()

1, adopting the technology of separate room and air pulse and jet cleaning, it overcomes the shortcomings of the conventional pulse dust collector and the chamber counter blowing dust collector. It has strong cleaning ability, high dust removal efficiency, low emission concentration, small air leakage rate and less energy consumption.

2, due to the use of air separation, pulse blowing and ash cleaning, it can achieve the purpose of thorough ash cleaning once a time is injected. Therefore, the cleaning period is extended, and the energy consumption of ash cleaning is reduced, and the consumption of compressed air can be greatly reduced.

3. The repair and replacement bag can be carried out in the division room under the normal operating condition of the system. The bag mouth of the filter bag adopts elastic ring, and its sealing performance is good, and it is firm and reliable.

4, the upper oil bag, bag change is removed from the skeleton, dirty bag into the lower part of the box body is taken from the hopper, Kong Chu, to improve the operating conditions for bags.

5, the air tightness design is adopted in the box, and the sealing material is good. The fine sealing material is used to check the door. The leakage rate of the kerosene is low in the process of making the kerosene.

6, the inlet and outlet duct arrangement is compact, and the air flow resistance is small.